M2P Engineering provide structural, mechanical and piping construction, maintenance and engineering services from mine to port.

We also provide patented inflatable Minvent Products. These products are custom-made, innovative solutions for, overhead protection, underground mine ventilation control and sealing solutions.

M2P Engineering has a comprehensive health, safety, environment, quality and community policy. Various management plans are available to our clients and we have attained the following ISO certifications; ISO 9001, ISO 14001 and ISO 45001.

We have a significant new and fit-for-purpose fleet of underground capable construction plant and equipment, including cranes, tilt tray and light trucks, boom lifts, scissor lifts, telehandlers and light vehicles.

M2P Engineering’s project capabilities extend to all structural, mechanical and piping (SMP) scope of major infrastructure projects.

Below is an overview of the SMP projects M2P has delivered to date in Australia.

Underground Primary Crushing & Ore Handling Systems

Primary Crushing Stations – M2P has installed new primary gyratory crushers, tipples, crusher feed pockets, and discharge pockets.

Crushed Ore Bins – M2P has installed crushed ore bins of various capacities.

Tramp Removal Areas – M2P has installed Tramp Removal Systems, including Apron Feeders, Picking/Collection Conveyors, Magnets and Metal Detectors.

Primary Ventilations Systems

M2P has installed Primary Ventilation systems, with fan capacities up to 1.75MW each. Such installations also include underground hydraulic ventilation doors and associated equipment.

Mine Services

M2P has installed various mine services, such as raw and fire water storage tanks, compressed air and associated piping, break tanks and dewatering rising mains.

Concrete Batching Plants

M2P has installed concrete batching plants, consisting of all hoppers, tanks and services, with capacities up to 60m3/hr.

Portal Conveyor & Surface Transfer Stations

M2P has installed conveyor and transfer stations capable of moving product from underground, through portals and onto surface infrastructure.

Marine and Ship Modifications, Maintenance & Repairs

M2P has a team of specially qualified trades people with decades of experience working in the marine and shipping sectors.

- Lloyds Register certified welders

- Loading port and deck hole adaptor fabrication

- Marine Security Identification Card holding and various ports-inducted personnel.

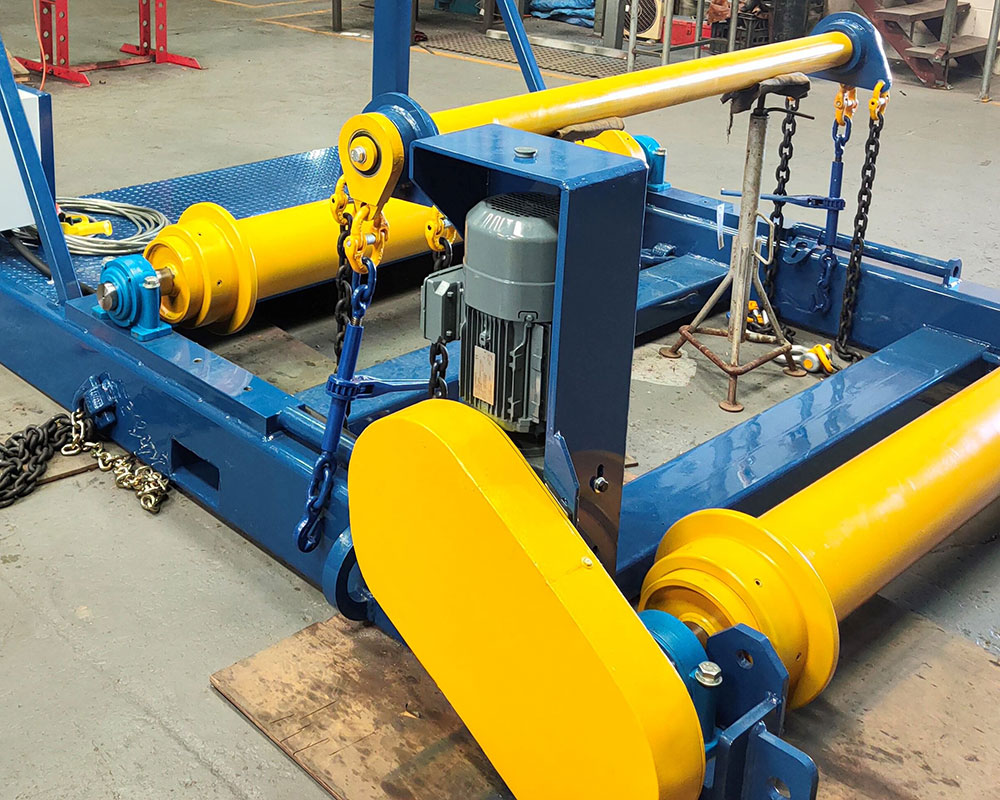

Bulk Materials Handling & Plant Maintenance Systems

We have an in depth understanding of materials handling systems, acquired from years of experience at high performing operations.

- Mechanical maintenance services

- Component refurbishment

- Steel fabrication

- Chute maintenance and fabrication

- Crushing and wear consumables.

Engineering, Fabrication, Welding, Machining & Fitting

With workshops in Brisbane and in Perth, we literally offer Australia our services from east coast to west. We perform mechanical, steel and PVC-coated-fabric manufacturing and engineering services.

- Steel and PVC-fabric welding

- Mechanical machining and manufacturing

- Technical engineering design & drafting.

MANAGEMENT PROJECT EXPERIENCE

M2P Engineering’s management has extensive experience in constructing and maintaining major infrastructure projects in the resources industry. Here’s a selection of our Project Management Consulting experience to date.

Ernest Henry Mine Expansion

Capricorn Copper Mine Project

Pasar Smelter Expansion

Pilgangoora Processing Plant

For further information regarding M2P Engineering, please download a copy of our Capability Statement today.